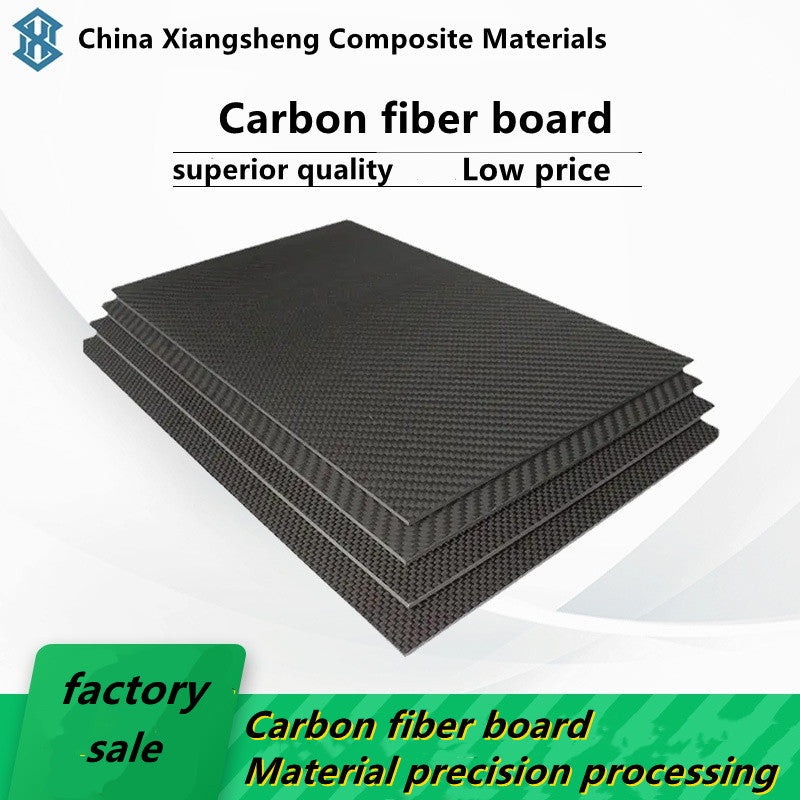

Xiangsheng Carbon Fiber

Carbon fiber plates

Carbon fiber plates

无法加载取货服务可用情况

Comprehensive Guide to Carbon Fiber Sheets: Benefits, Applications, and Manufacturing Process

Carbon fiber sheets are a high-performance composite material known for their lightweight, high strength, and corrosion resistance. These sheets are widely used in industries such as aerospace, automotive manufacturing, construction, and sports equipment. Carbon fiber sheets not only offer exceptional mechanical properties but are also resistant to physical and chemical wear, making them indispensable in modern industrial applications.

1. What are Carbon Fiber Sheets?

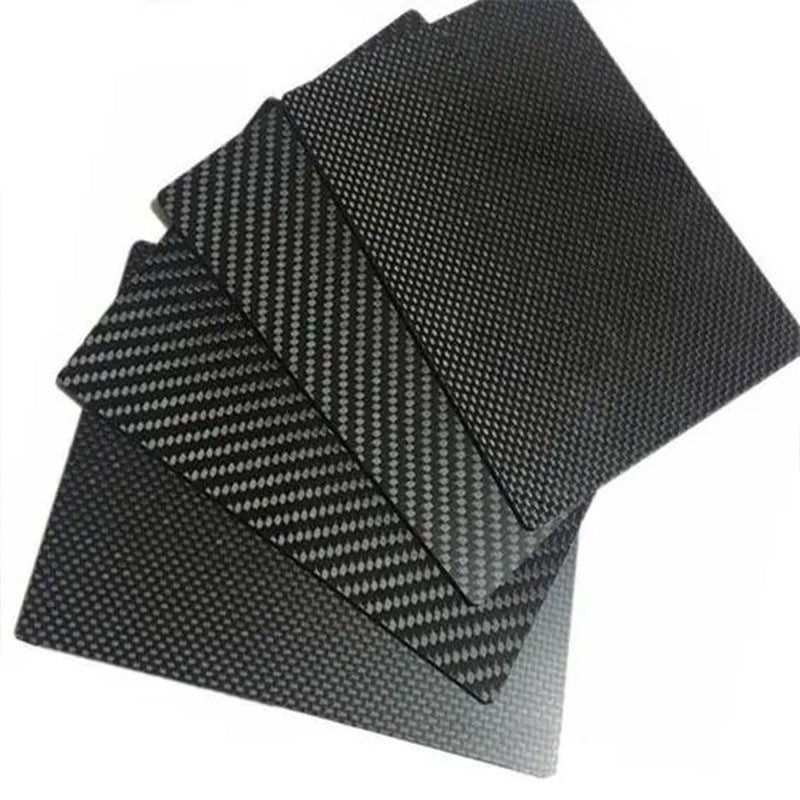

Carbon fiber sheets are composite materials made by combining carbon fiber reinforcement with a resin matrix, formed under high temperature and pressure. The molecular structure of carbon fiber resembles a graphene-like lattice, providing both rigidity and flexibility. Carbon fiber sheets typically have a multi-layer structure, with the layers bonded by resin or epoxy resin, giving them extraordinary tensile strength and fatigue resistance.

2. Advantages of Carbon Fiber Sheets

-

Lightweight: Carbon fiber sheets have a density only 1/4 that of steel, yet their strength can reach seven times that of steel. This light weight and high strength make them ideal for use in industries like aerospace and racing, where weight reduction is critical.

-

High Strength and Durability: The molecular arrangement of carbon fibers gives them excellent tensile strength, making them less prone to breakage compared to traditional materials. Additionally, carbon fiber materials are corrosion-resistant, maintaining stability even in harsh environments.

-

Heat and Chemical Resistance: Carbon fiber sheets can withstand temperatures of up to 3000°C and exhibit good chemical resistance, ensuring they do not degrade or age easily in most environments.

-

Design Flexibility: Carbon fiber sheets can be custom-manufactured to meet specific design needs, with the shape and thickness tailored to different applications.

3. Applications of Carbon Fiber Sheets

-

Aerospace: Due to their light weight and high strength, carbon fiber sheets are extensively used in manufacturing aircraft wings, fuselages, and satellite components.

-

Automotive Industry: Carbon fiber sheets are used in body panels, chassis, and engine hoods in high-performance cars and luxury vehicles to reduce weight and improve fuel efficiency and performance.

-

Construction and Infrastructure: Carbon fiber sheets are often used in structural reinforcement, especially in bridges and high-rise buildings, enhancing seismic performance and durability.

-

Sports Equipment: In products such as bicycle frames, tennis rackets, and golf clubs, carbon fiber sheets provide the ideal combination of strength and lightweight performance for high-end sports gear.

4. Carbon Fiber Sheet Manufacturing Process

The production of carbon fiber sheets typically involves the following steps:

-

Preparation of Carbon Fiber Prepreg: Carbon fiber strands are combined with resin to create prepreg material.

-

Layering and Shaping: Prepreg layers are stacked and placed into molds according to design requirements, ensuring each layer’s fiber direction and thickness meet specific standards.

-

Curing: Heat and pressure are applied to cure the resin, bonding the carbon fibers to form a strong sheet.

-

Post-processing: After curing, the sheets undergo cutting, sanding, and other finishing processes based on specific application requirements.

5. How to Choose Carbon Fiber Sheets?

When selecting carbon fiber sheets, several factors need to be considered:

- Purpose: Different applications require varying levels of thickness, strength, and durability.

- Layer Count and Thickness: Generally, more layers result in higher strength, but this also increases weight and cost.

- Surface Finish: In some cases, surface treatments such as coatings or textures are needed to improve aesthetics or add anti-slip properties.

6. Future Trends in Carbon Fiber Sheets

As technology advances, the production costs of carbon fiber sheets are expected to decrease, while performance continues to improve. In the future, carbon fiber materials will likely see increased use in mass-market vehicles, structural reinforcement, and other areas, driving innovation across multiple industries.

Share