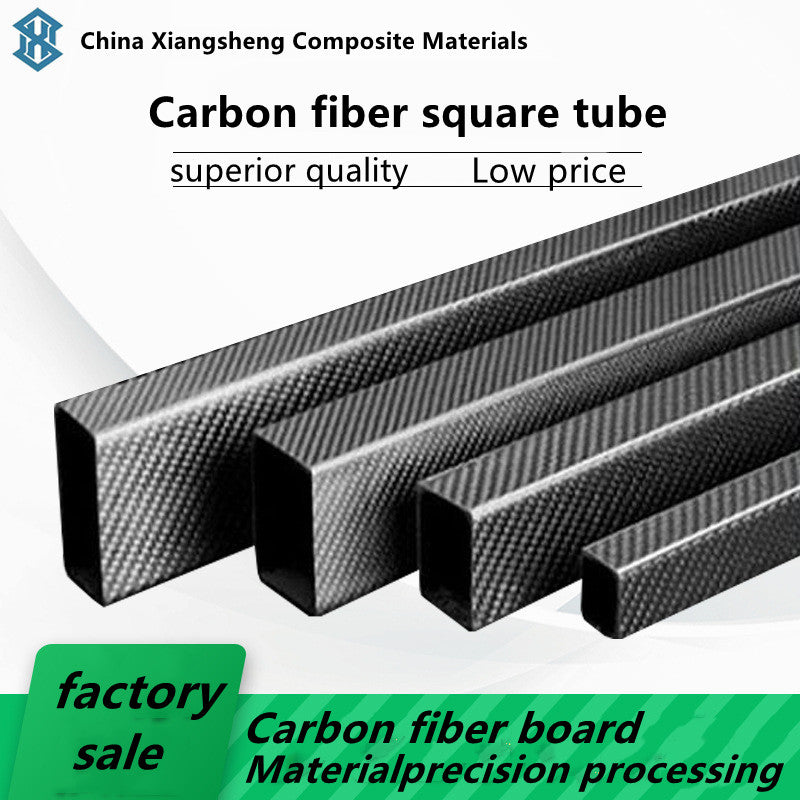

Xiangsheng

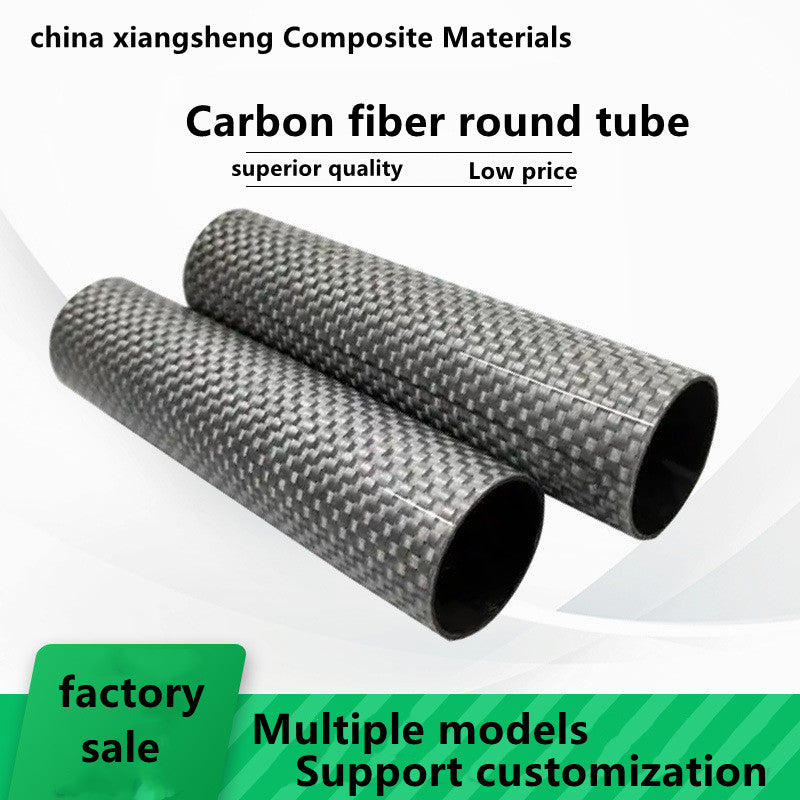

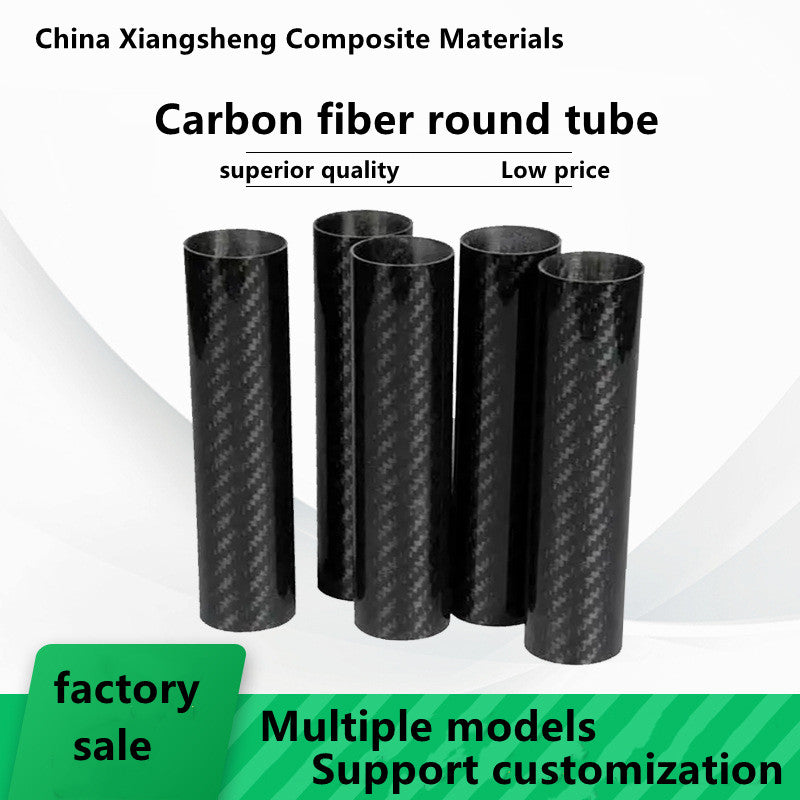

Carbon fiber round tube

Carbon fiber round tube

无法加载取货服务可用情况

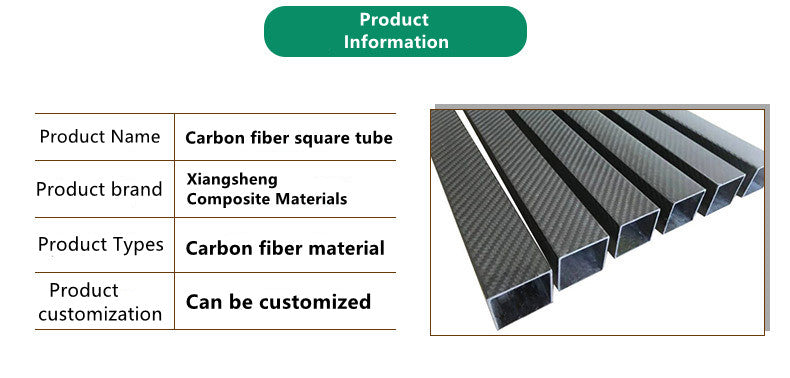

Carbon Fiber Round Tube Details

I. Introduction

Carbon fiber round tubes have emerged as a remarkable material in various industries due to their exceptional properties and versatility. These tubes are made from carbon fiber, a strong and lightweight material that offers a unique combination of strength, stiffness, and low weight.

II. Material Composition

1. Carbon Fiber

- Carbon fiber is composed mainly of carbon atoms. It is produced by a process that involves the conversion of organic fibers, such as polyacrylonitrile (PAN) or pitch, into carbon fiber through a series of thermal and chemical treatments.

- The carbon fiber used in round tubes is typically high-quality and has a high carbon content, which contributes to its excellent mechanical properties.

2. Resin Matrix

- To bind the carbon fibers together and form a solid structure, a resin matrix is used. Commonly used resins include epoxy resin. The resin not only holds the carbon fibers in place but also plays a role in transferring loads between the fibers and protecting them from environmental factors.

III. Manufacturing Process

1. Filament Winding

- This is a common method for manufacturing carbon fiber round tubes. In filament winding, continuous carbon fiber filaments are wound around a mandrel in a specific pattern and angle. The winding angle can be adjusted to optimize the mechanical properties of the tube, such as its strength in different directions.

- After winding, the resin is applied either during the winding process (wet winding) or afterwards (dry winding followed by resin impregnation). The tube is then cured in an oven at a controlled temperature and time to harden the resin and bond the carbon fibers firmly.

2. Pultrusion

- In the pultrusion process, carbon fibers are pulled through a die that is filled with resin. As the fibers and resin pass through the die, they are shaped into a round tube. The pultrusion process allows for continuous production of high-quality tubes with consistent properties.

- After extrusion, the tube is also cured to achieve the desired mechanical and physical properties.

IV. Properties

1. Mechanical Properties

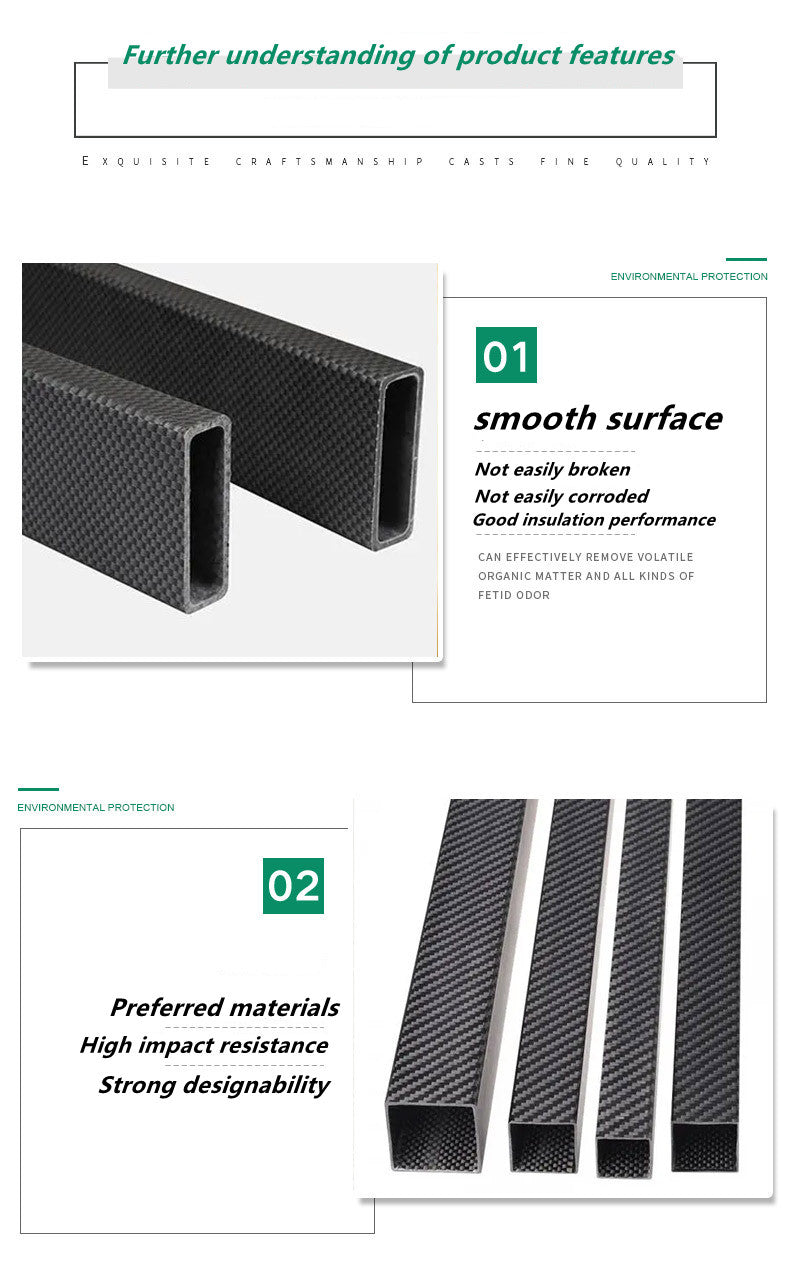

- High Strength: Carbon fiber round tubes have a very high tensile strength, which means they can withstand significant amounts of pulling or stretching forces without breaking. Their strength-to-weight ratio is much higher than that of many traditional materials such as steel and aluminum.

- High Stiffness: They exhibit excellent stiffness, providing good resistance to deformation under load. This makes them suitable for applications where dimensional stability is crucial, such as in structural components.

- Lightweight: The density of carbon fiber is much lower than that of metals, resulting in lightweight tubes. This is beneficial in applications where weight reduction is important, such as in aerospace, automotive, and sports equipment.

2. Chemical Properties

- Corrosion Resistance: Carbon fiber is highly resistant to corrosion. It does not rust or deteriorate in the presence of moisture, chemicals, or most environmental conditions. This makes the round tubes suitable for use in harsh environments and applications where durability is essential.

3. Thermal Properties

- Low Thermal Expansion: Carbon fiber round tubes have a relatively low coefficient of thermal expansion. This means they expand and contract less with changes in temperature compared to some other materials, which can be important in applications where dimensional accuracy needs to be maintained over a wide temperature range.

- Good Thermal Conductivity: They also have moderate thermal conductivity, which can be beneficial in some applications where heat dissipation or transfer is required.

V. Applications

1. Aerospace Industry

- In aircraft and spacecraft, carbon fiber round tubes are used for various structural components such as wing spars, fuselage frames, and antenna masts. Their lightweight and high-strength properties help to reduce the overall weight of the vehicle, improving fuel efficiency and performance.

2. Automotive Industry

- They are used in the manufacturing of automotive parts like chassis components, drive shafts, and exhaust pipes. The use of carbon fiber round tubes can enhance the performance and handling of vehicles while also contributing to fuel economy through weight reduction.

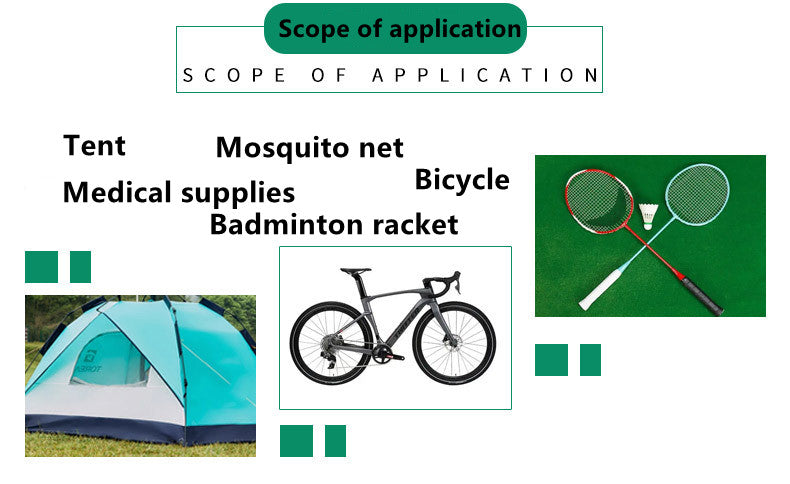

3. Sports Equipment

- In the production of bicycles, golf clubs, fishing rods, and other sports equipment, carbon fiber round tubes are popular due to their lightweight and excellent mechanical properties. They can improve the performance and maneuverability of the equipment, giving athletes an edge.

4. Medical Equipment

- Carbon fiber round tubes are used in the construction of medical devices such as crutches, wheelchairs, and surgical instruments. Their lightweight and corrosion-resistant properties make them suitable for these applications, and they can also be sterilized easily.

5. Industrial Machinery

- In various industrial machines and equipment, carbon fiber round tubes can be used for structural supports, conveyor rollers, and robotic arms. Their high strength and stiffness make them reliable in industrial settings.

VI. Advantages

1. Weight Reduction

- As mentioned earlier, the lightweight nature of carbon fiber round tubes can lead to significant weight savings in applications where every gram counts. This can result in improved energy efficiency, increased payload capacity, and better overall performance.

2. Strength and Durability

- Their high strength and durability ensure a long service life and reliable performance even in demanding conditions. They can withstand heavy loads, vibrations, and environmental stresses, making them a cost-effective choice in the long run.

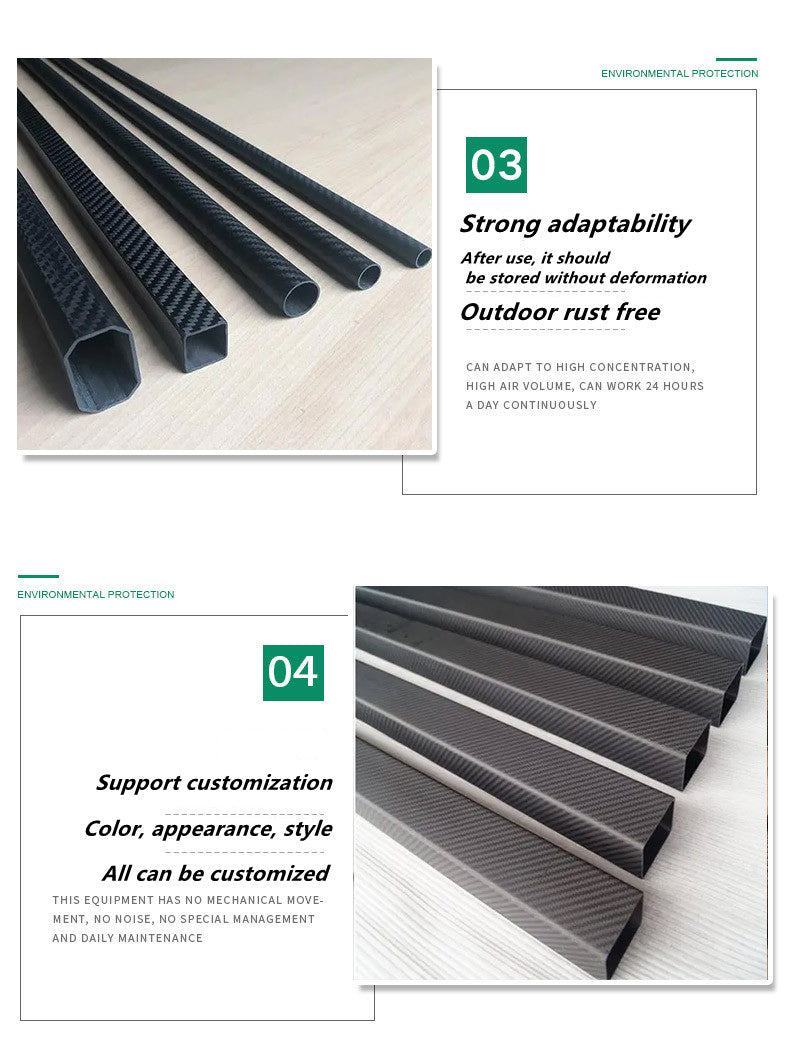

3. Design Flexibility

- Carbon fiber round tubes can be manufactured in different diameters, lengths, and wall thicknesses to meet specific design requirements. They can also be customized with various surface finishes and coatings. This design flexibility allows engineers to optimize the performance and appearance of the tubes for different applications.

4. Corrosion Resistance

- The resistance to corrosion means less maintenance and replacement over time, especially in applications where the tubes are exposed to harsh environments or chemicals. This can result in significant cost savings and increased operational reliability.

VII. Disadvantages

1. High Cost

- The production process of carbon fiber round tubes is relatively complex and requires advanced technology and high-quality raw materials. This leads to a higher cost compared to many traditional materials, which can limit their widespread use in some applications where cost is a major factor.

2. Brittleness

- Although carbon fiber is strong, it can be relatively brittle. This means that it may not be as tolerant of impact or sudden loads as some other materials. Special care may need to be taken in handling and designing with carbon fiber round tubes to avoid damage.

3. Difficult Repairability

- Repairing carbon fiber round tubes can be challenging. If a tube is damaged, it often requires specialized skills and equipment to repair it properly. In some cases, it may be more cost-effective to replace the damaged tube rather than repair it.

VIII. Maintenance and Care

1. Cleaning

- Carbon fiber round tubes should be cleaned regularly to remove dirt, dust, and other contaminants. A mild detergent and soft cloth can be used for cleaning. Avoid using abrasive cleaners that could damage the surface of the tube.

2. Inspection

- Periodic inspection is important to check for any signs of damage, such as cracks, dents, or delamination. Any damage should be addressed promptly to prevent further deterioration and ensure the safety and performance of the tube.

3. Storage

- When not in use, carbon fiber round tubes should be stored in a dry and clean environment. Avoid exposing them to direct sunlight or extreme temperatures, as this can affect their properties over time. They should also be stored in a way that prevents them from being bent or deformed.

In conclusion, carbon fiber round tubes offer a wide range of advantages in terms of their mechanical, chemical, and thermal properties. They have found numerous applications in various industries, but also come with some disadvantages such as high cost and difficult repairability. Proper maintenance and care can help to extend their lifespan and ensure their optimal performance. Understanding the details of carbon fiber round tubes is crucial for engineers, designers, and users to make informed decisions about their use and application.

Share